The K-drip tape irrigation pipe

The K-drip tape irrigation pipe is manufactured using seamless extrusion technology. The method of production of the drip tape irrigation pipe guarantees the impossibility to bend the pipe, disturb the flow and problems when starting the system.

K-drip is a special system with a continuous labyrinth, providing high resistance to clogging, longer use of the system and rational use of water.

The K-drip tape irrigation pipe

The K-drip tape irrigation pipe is characterized by:

• Seamless construction for higher stability

• High quality raw materials, resistant to weather conditions and soil damage

• High resistance to tension and cracking

• Double water filtration through 110 precisely located points

• The turbulent labyrinth is designed for high clogging resistance

• Precisely shaped emitters for high flow uniformity

• Precise emitters with micro slits eliminate possible blockages when starting the system

• Clearly visible white lines for better recognition of the position of the pipe and emitters

• Available with different distances between emitters and drip flow

The K-drip tape irrigation pipe

The K-drip tape irrigation pipe provides high-tech solutions for irrigation and improving the fertility of garden and flower crops outdoors (such as corn, tomatoes, potatoes, carrots, onions, strawberries, roses, cloves); allows precise supply of water and nutrients for each plant where needed; provides protection of natural resources.

Characteristics

| φ 16 | |||||

| diameter | mil/mic | inside diameter | outside diameter | min pressure | max pressure |

| 16mm | 6mil{150mic} | 16.1mm | 16.4mm | 0.7 bar | 1.2 bar |

| 16mm | 8mil{200mic} | 16.1mm | 16.5mm | 0.7 bar | 1.7 bar |

| 16mm | 10mil{250mic} | 16.1mm | 16.6mm | 0.7 bar | 2.1 bar |

| 16mm | 12mil{300mic} | 16.1mm | 16.7mm | 0.7 bar | 2.4 bar |

| φ 22 | ||||

| diameter | mil/mic | inside diameter | min pressure | max pressure |

| 22mm | 7mil/0.178mm | 22.55mm | 0.3 bar | 0.6 bar |

| 22mm | 8mil/0.20mm | 22.6mm | 0.3 bar | 0.7 bar |

| 22mm | 10mil/0.25mm | 22.7mm | 0.3 bar | 1 bar |

| φ 16 | ||||

| mils | mil/mic | distance between emitters | flow L / emitter | length of the roll |

| 6 | 6mil{150mic} | 10см/ 20см/ 30см/40см | 0.6l/h | 3000m |

| 6 | 6mil{150mic} | 10см/ 20см/ 30см/40см | 1.0l/h | 3000m |

| 6 | 6mil{150mic} | 10см/ 20см/ 30см/40см | 1.5l/h | 3000m |

| 8 | 8mil{200mic} | 10см/ 20см/ 30см/40см | 0.6l/h | 2500m |

| 8 | 8mil{200mic} | 10см/ 20см/ 30см/40см | 1.0l/h | 2500m |

| 8 | 8mil{200mic} | 10см/ 20см/ 30см/40см | 1.5l/h | 2500m |

| φ 22 | ||||

| mils | mil/mic | distance between emitters | flow L / emitter | length of the roll |

| 8 | 6mil{150mic} | 10см/ 20см/ 30см/40см | 0.6l/h | 1500m |

| 8 | 6mil{150mic} | 10см/ 20см/ 30см/40см | 1.0l/h | 1500m |

| 8 | 6mil{150mic} | 10см/ 20см/ 30см/40см | 1.5l/h | 1500m |

| 10 | 8mil{200mic} | 10см/ 20см/ 30см/40см | 0.6l/h | 1200m |

| 10 | 8mil{200mic} | 10см/ 20см/ 30см/40см | 1.0l/h | 1200m |

| 10 | 8mil{200mic} | 10см/ 20см/ 30см/40см | 1.5l/h | 1200m |

| Recommended length of the application in meters 6mill/ ф16 0.7bar | |||||

| Spacing (cm) | |||||

| Emitter flow rate | Uniformity % | 10 | 20 | 30 | 40 |

| 0.6 l/h | 90% | 110 | 175 | 230 | 275 |

| 85% | 135 | 215 | 283 | 338 | |

| 1 l/h | 90% | 76 | 119 | 153 | 184 |

| 85% | 93 | 146 | 188 | 226 | |

| 1.5 l/h | 90% | 60 | 65 | 124 | 151 |

| 85% | 74 | 80 | 153 | 186 | |

| Recommended length of the application in meters 8mill/ ф22 0.7bar | |||||

| Spacing (cm) | |||||

| Emitter flow rate | Uniformity % | 10 | 20 | 30 | 40 |

| 0.6 l/h | 90% | 193 | 306 | 403 | 481 |

| 85% | 237 | 377 | 495 | 592 | |

| 1 l/h | 90% | 133 | 208 | 268 | 322 |

| 85% | 164 | 256 | 329 | 396 | |

| 1.5 l/h | 90% | 98 | 119 | 193 | 245 |

| 85% | 121 | 146 | 237 | 301 | |

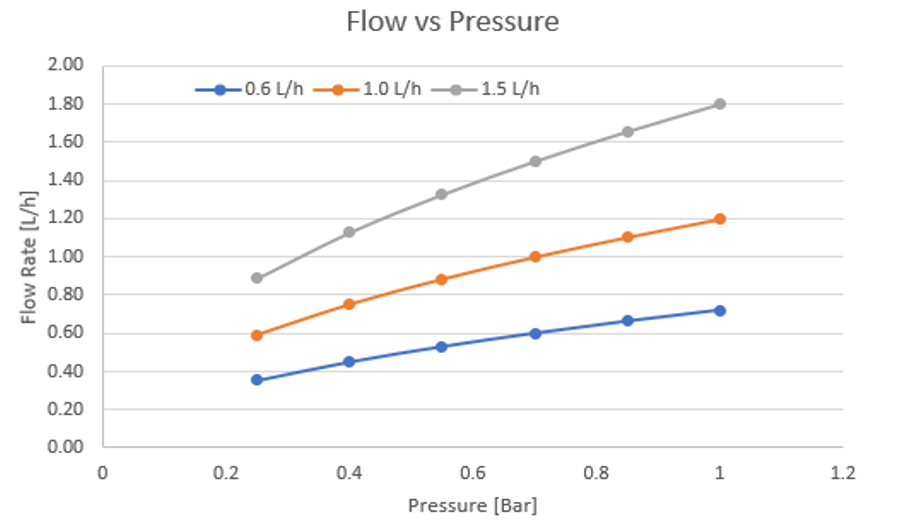

Tape labyrinth Flow spec

| Flow rate [L/h] at 0.7 Bar | Pressure vs Flow rate in Bar | Constant K | Exponent X | Reccomended filtration Micron/Mesh | |||||

| 0,25 | 0,4 | 0,55 | 0,7 | 0,85 | 1 | ||||

| 0.6 l/h | 0,36 | 0,45 | 0,53 | 0,6 | 0,66 | 0,72 | 0,223 | 0,51 | 100/150 |

| 1 l/h | 0,59 | 0,75 | 0,88 | 1 | 1,1 | 1,2 | 0,37 | 0,51 | 100/150 |

| 1.5 l/h | 0,89 | 1,13 | 1,33 | 1,5 | 1,66 | 1,8 | 0,556 | 0,51 | 120/130 |